Product Design for Regulated Industries

What we do in:

Product Design for Regulated Industries

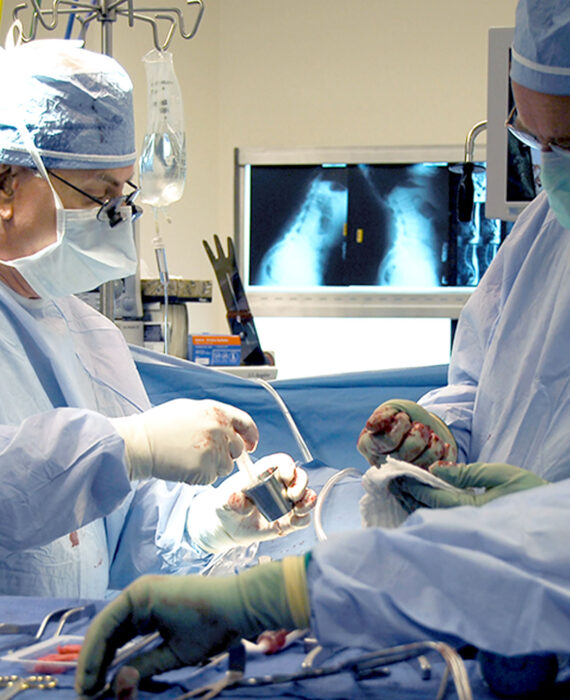

If you market products to the healthcare, aerospace, oil and gas, or any other highly regulated industry, you know how demanding creating those products can be. There’s little room for error, and the customer and regulatory requirements can be extreme. We have the know-how to develop these types of mission critical products to meet safety, regulatory, usability, functionality, and manufacturing requirements. When you serve these markets, you know that product failure can lead to loss of the brand equity you’ve worked hard to build, injury and worse. You need a development partner that understands this and has the process and skill you need to succeed.

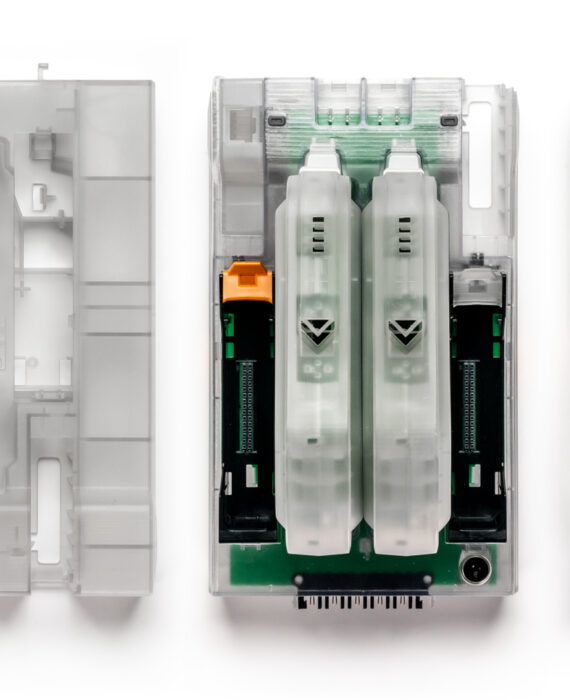

We begin your project with a strategy phase to define project success criteria that align with your business goals. We then conduct ethnographic and secondary research to define your stakeholder needs and project direction. Based on our findings, our team develops and tests concepts with stakeholders and then refines them until we find the optimal concept direction. We maintain direct contact with your supply chain and manufacturing teams to ensure the design meets your production and quality needs. Experienced engineers, designers, and support staff design your product and create a documentation package your supply chain can use to manufacture the product.

We ensure design intent and stakeholder needs are maintained as your product transitions from concept, to feasibility, to production to ensure it generates maximum revenue and profit.

Depending on your needs, the M3 team can support your production runs as your virtual engineering team, or simply be on-call to help you deal with issues during production ramp up.

- Risk Analysis

- Ethnographic Research

- Journey and Workflow Mapping

- Human Factors & Usability Assessments

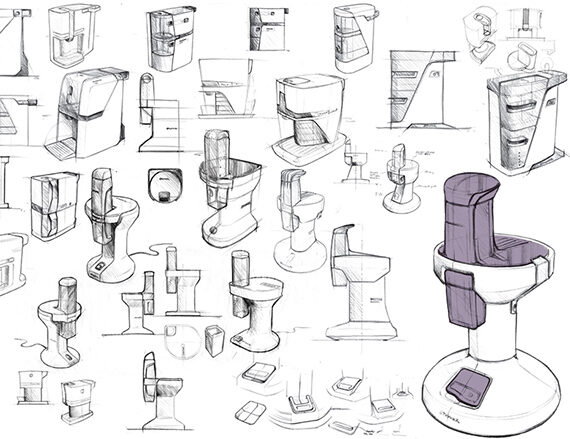

- Concept Development & Prototyping

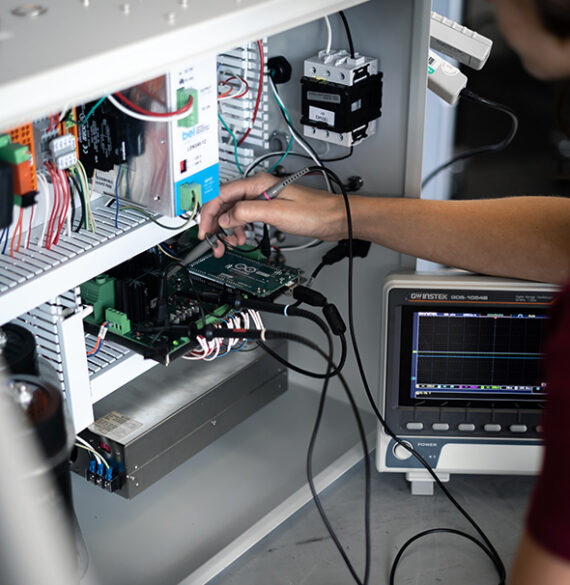

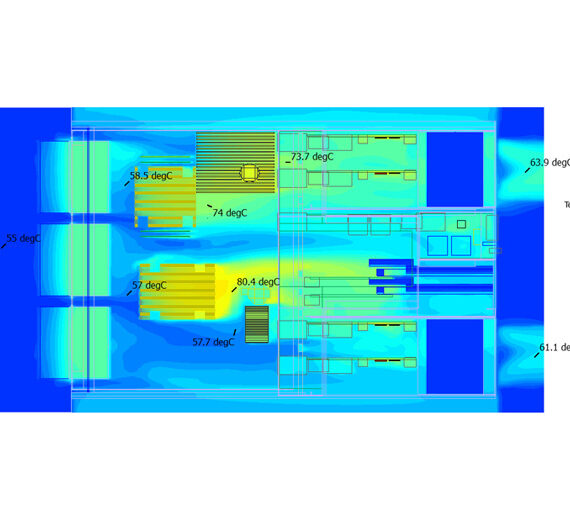

- Engineering Analysis

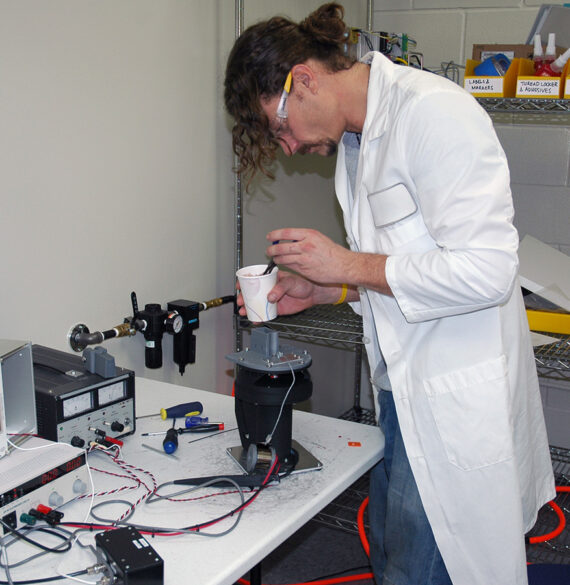

- Development Testing

- Formative and Usability Studies

- Certification Testing Support

- Detailed Parts and Assemblies

- Production Level Drawings

- Tolerance Analysis and GD&T

- Design Transfer Documentation

- Production Ramp-up Support

Our

Process

Strategy

Define the toughest design challenges, identify opportunities, and establish product success criteria to manage development risk.

Concept

Develop innovative concepts that optimize usability and functionality, while still meeting business objectives.

Explore those concepts, evaluate them against success criteria, and validate with key stakeholders.

Development

Translate the concept into a production solution, working closely with our client’s supply chain partners. Ensure that design intent and success criteria are maintained throughout manufacturing bring-up.

When the repercussions of your design decisions are a matter of life or death, you should work with a design and engineering firm with a proven track record of successfully innovating under such conditions.