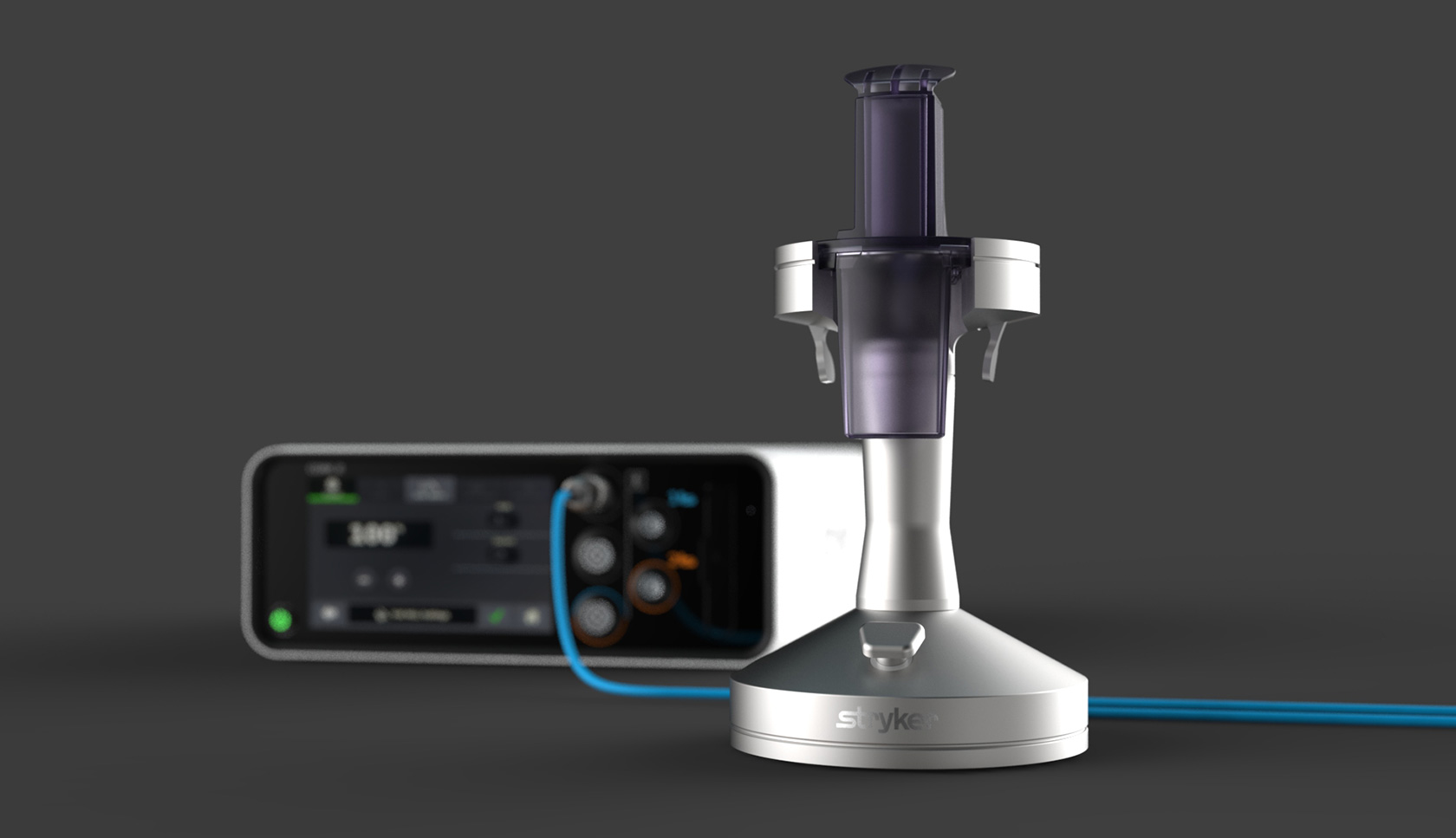

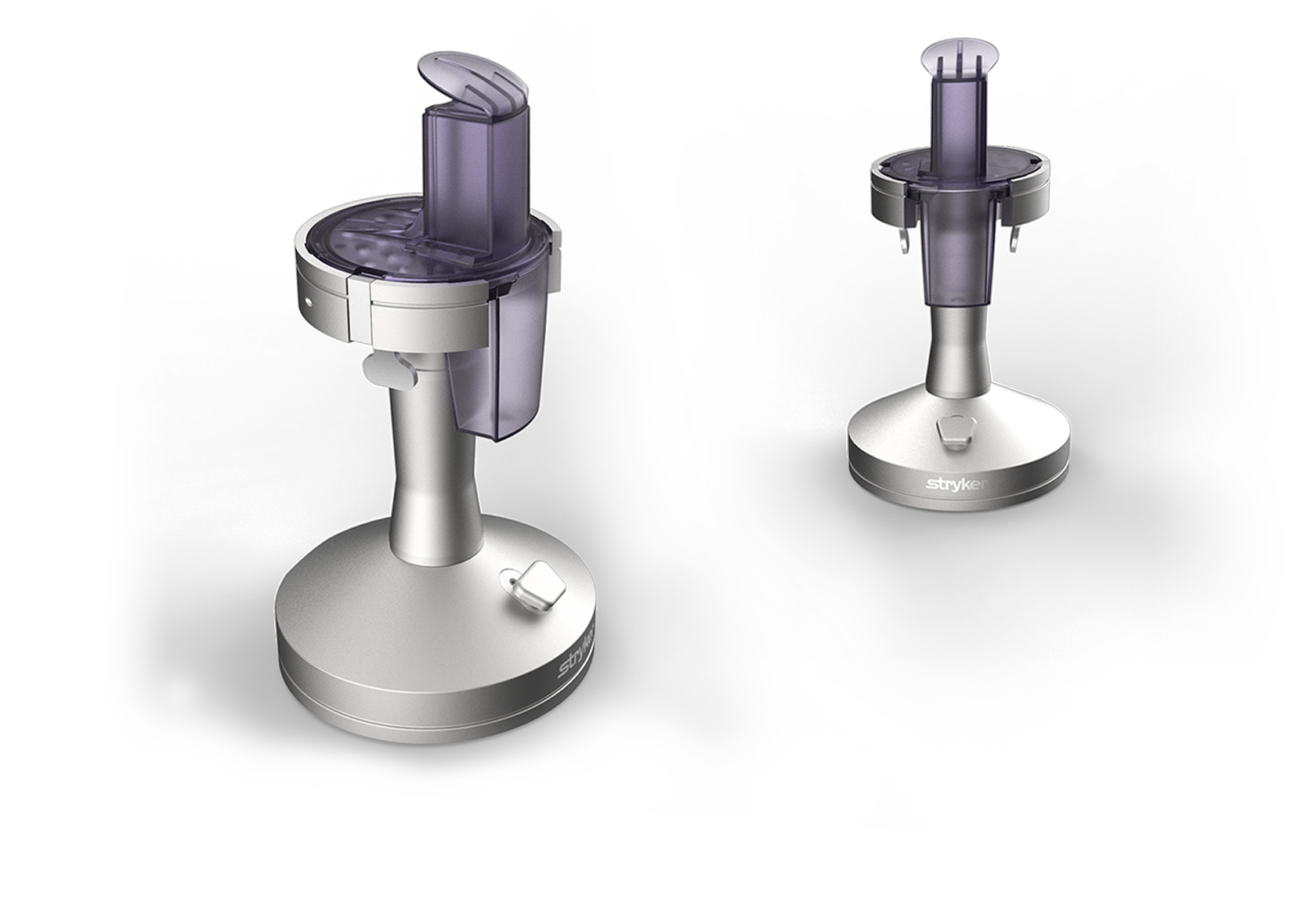

Developing a surgical device to fill a portfolio gap.

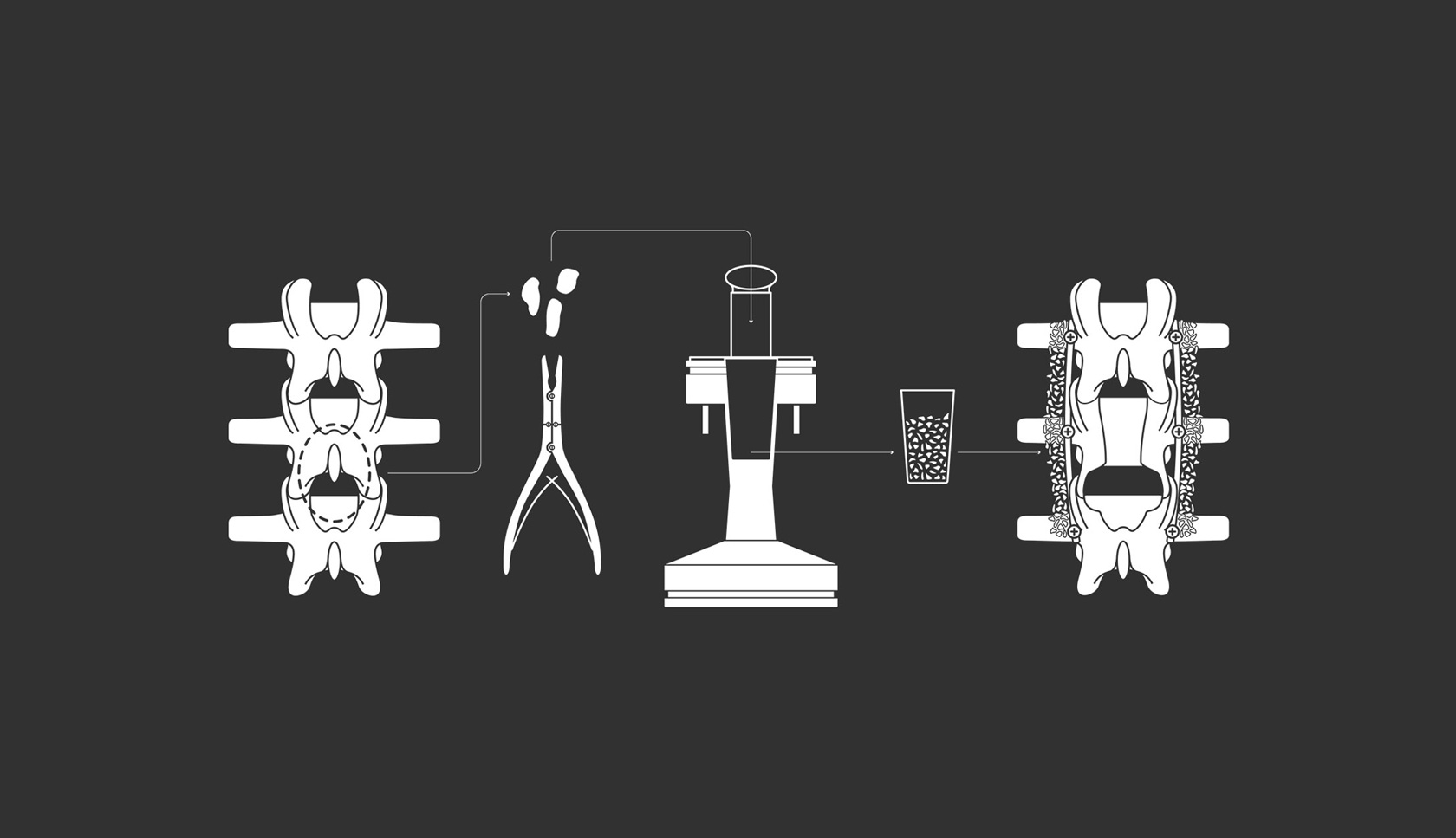

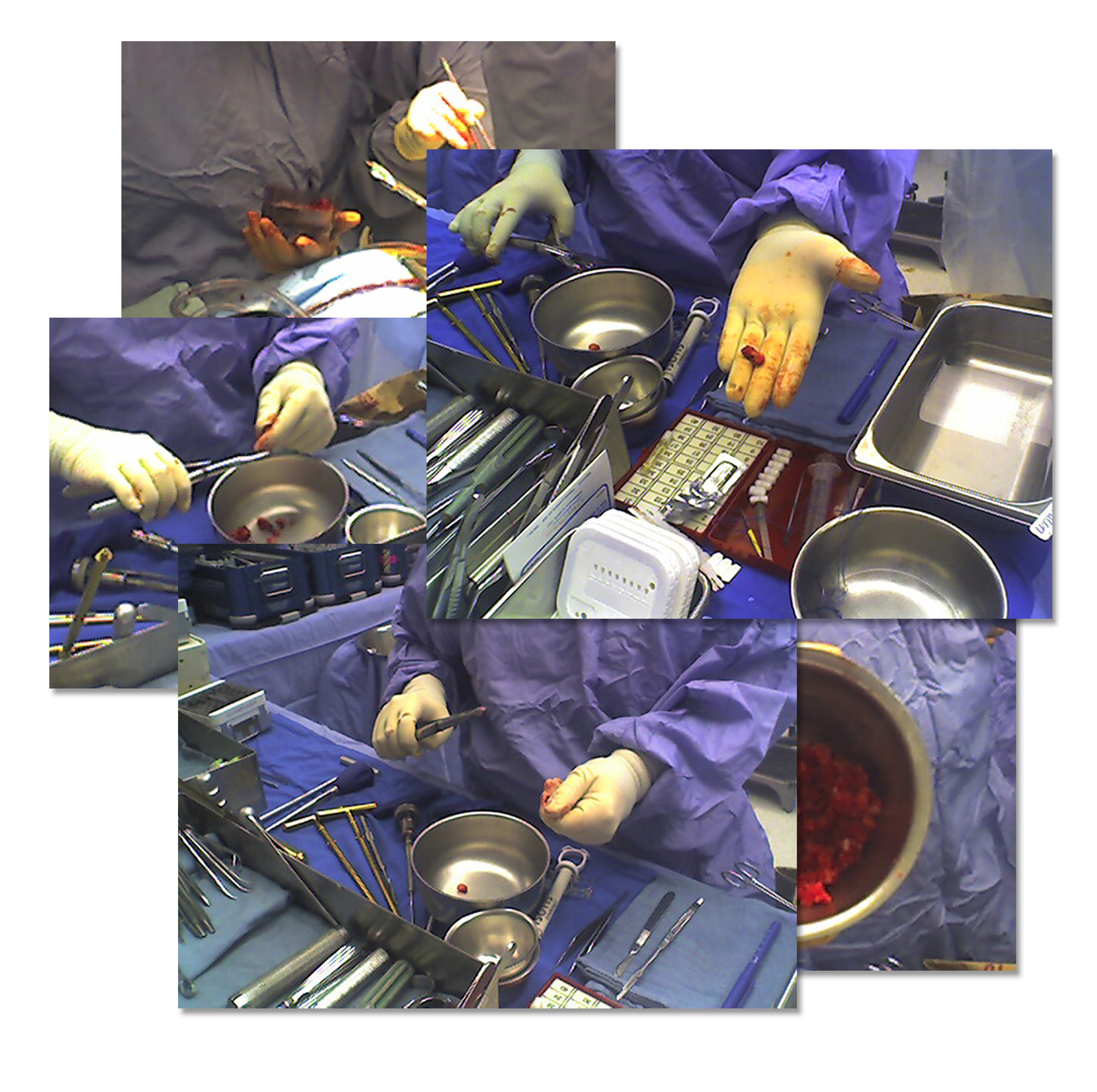

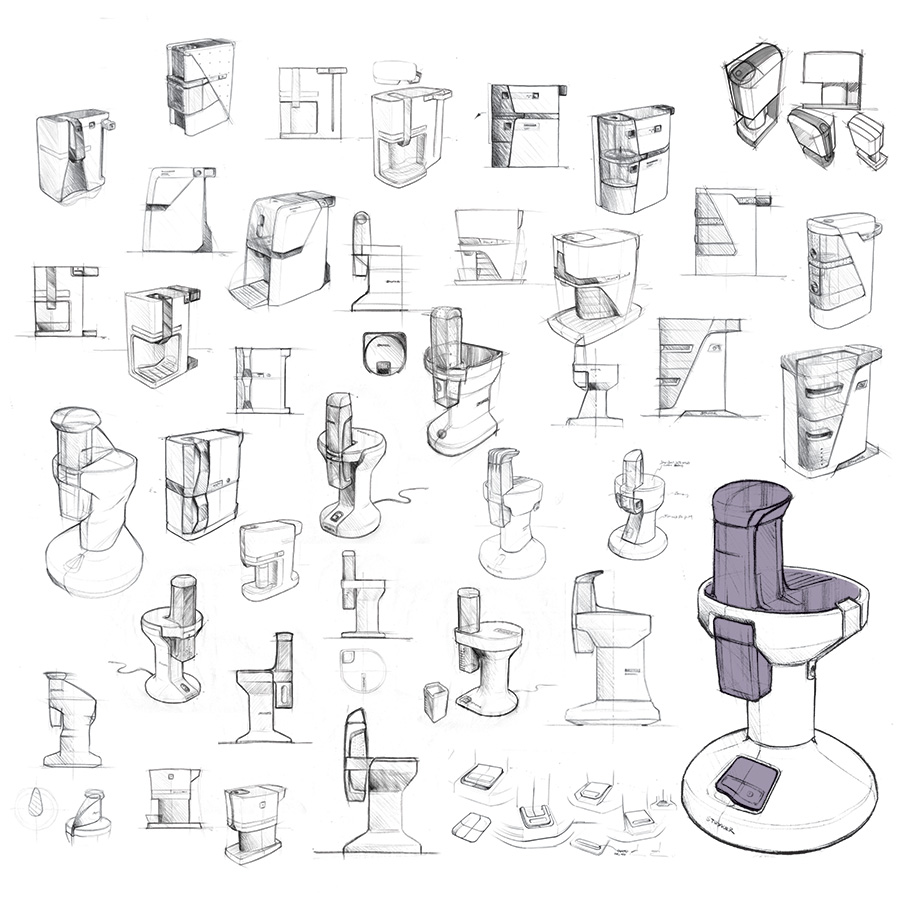

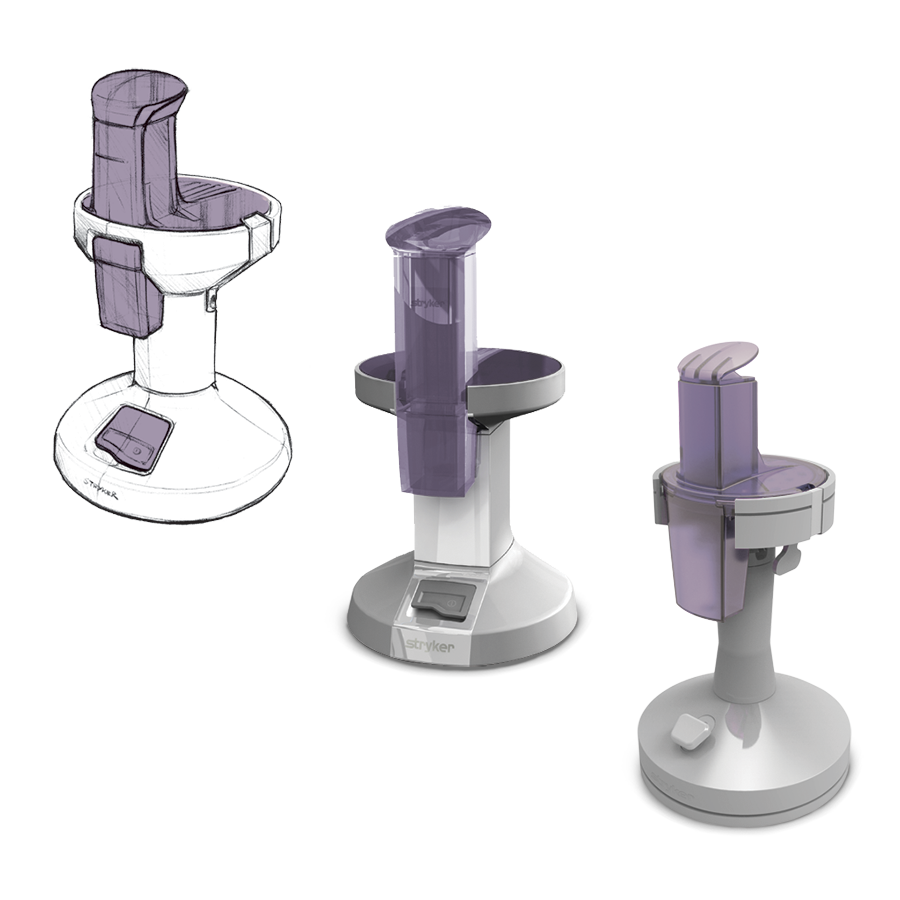

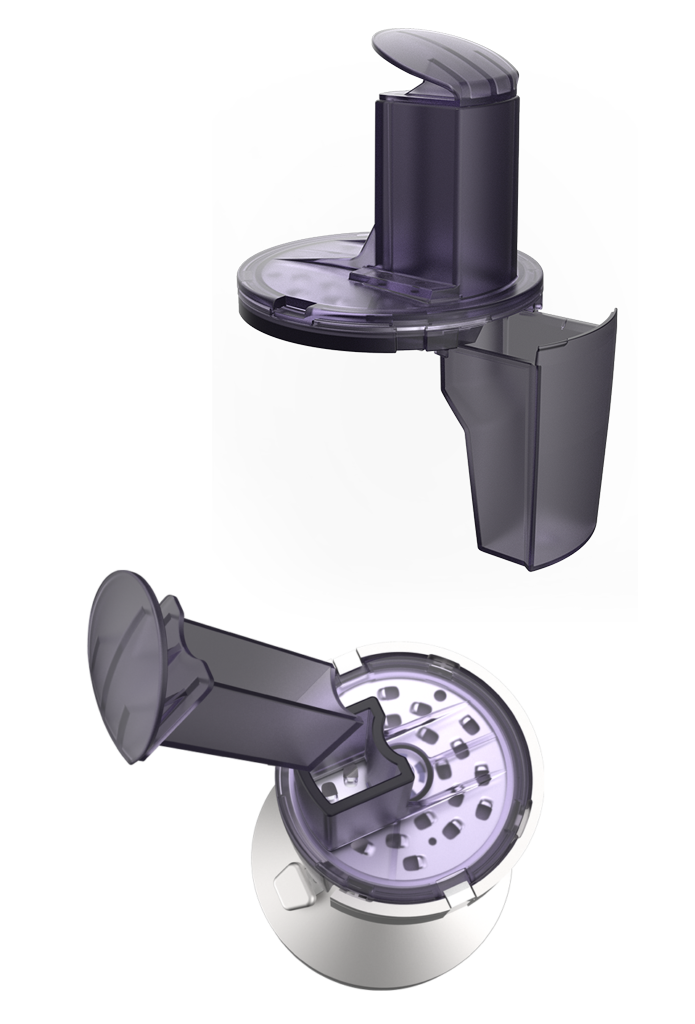

Spinal fusion surgery often requires that bone be harvested from the patient, reduced to a small and consistent size, and reintroduced into the patient to promote bone growth. Stryker identified an opportunity to replace this painstaking, manual process with an efficient powered solution. Stryker challenged M3 to design a best in class bone mill for surgeons and scrub nurses that met their needs and fit within their existing work-flow. The critical technical issues were how to consistently mill the desired sized bone chips while ensuring maximum cell viability and integrating with Stryker’s existing capital equipment products.