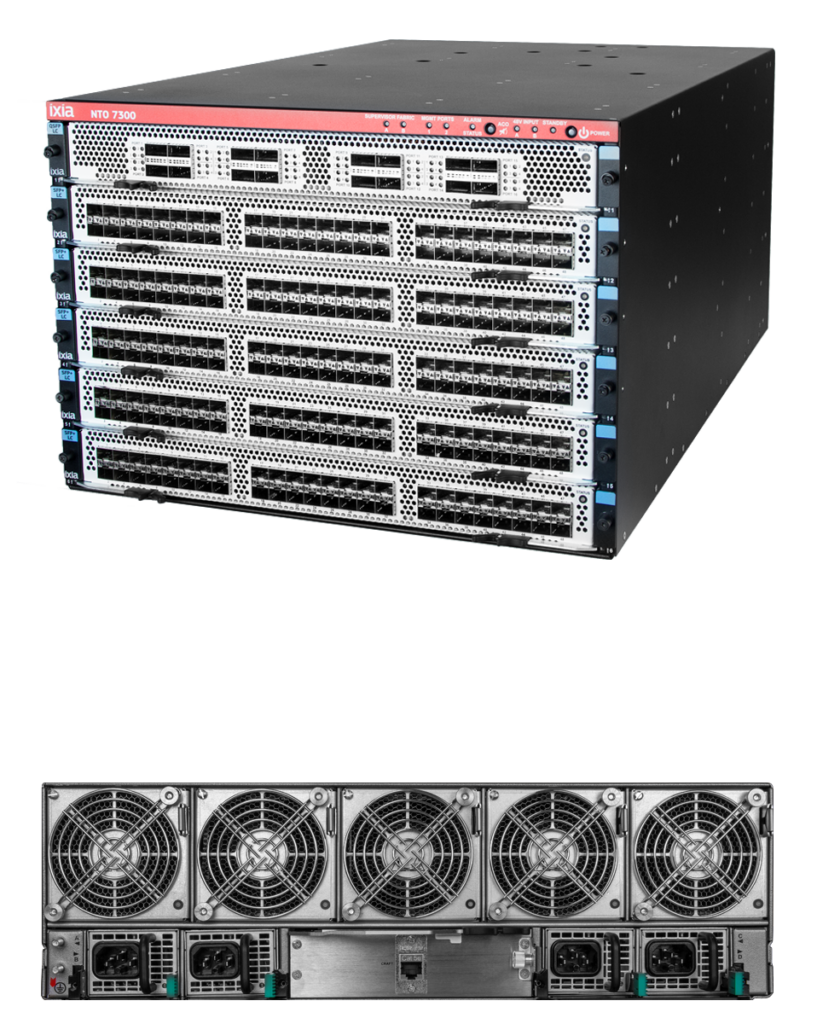

High-density, modular platforms for ultra-performance, and intelligent network visibility.

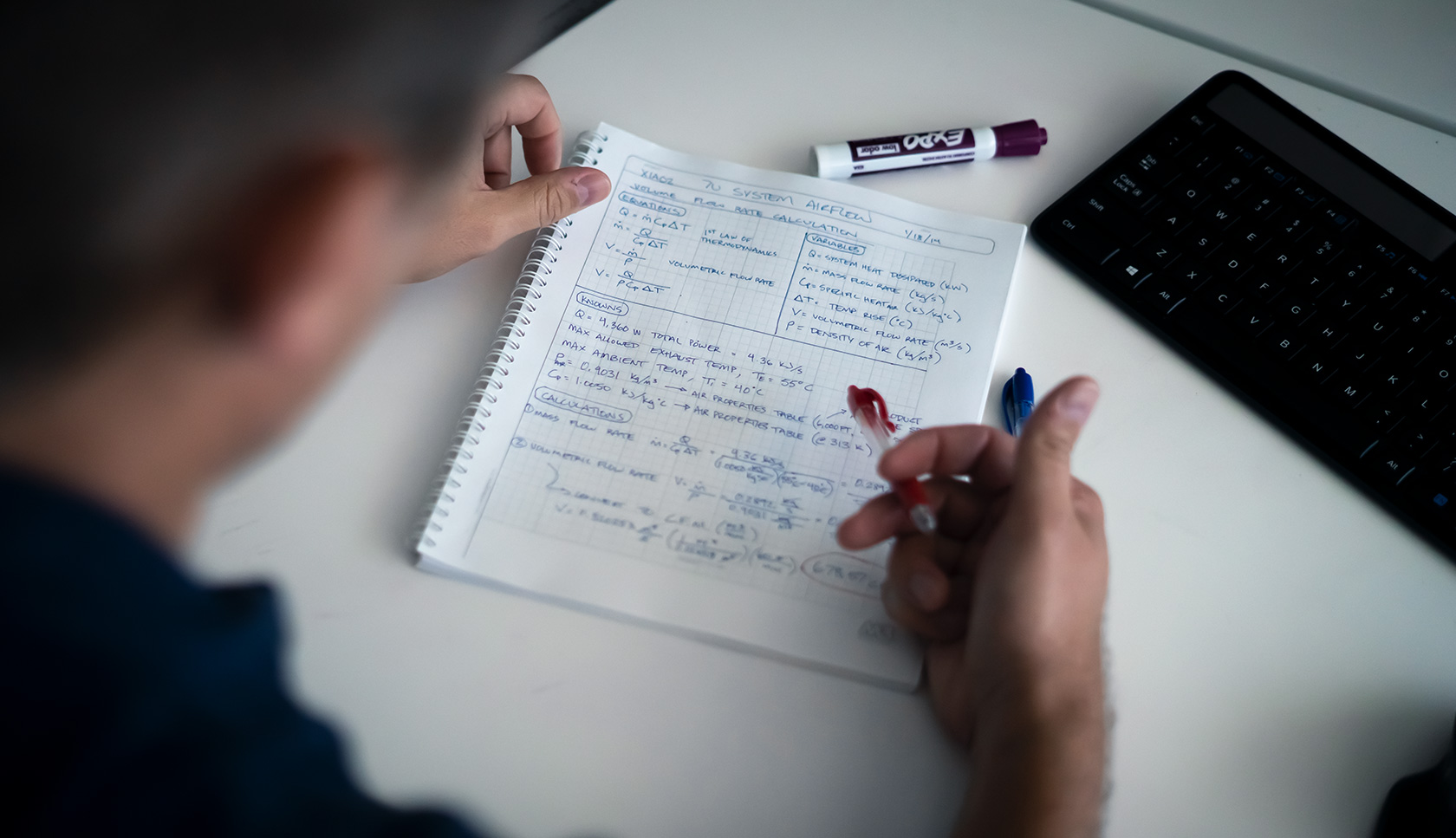

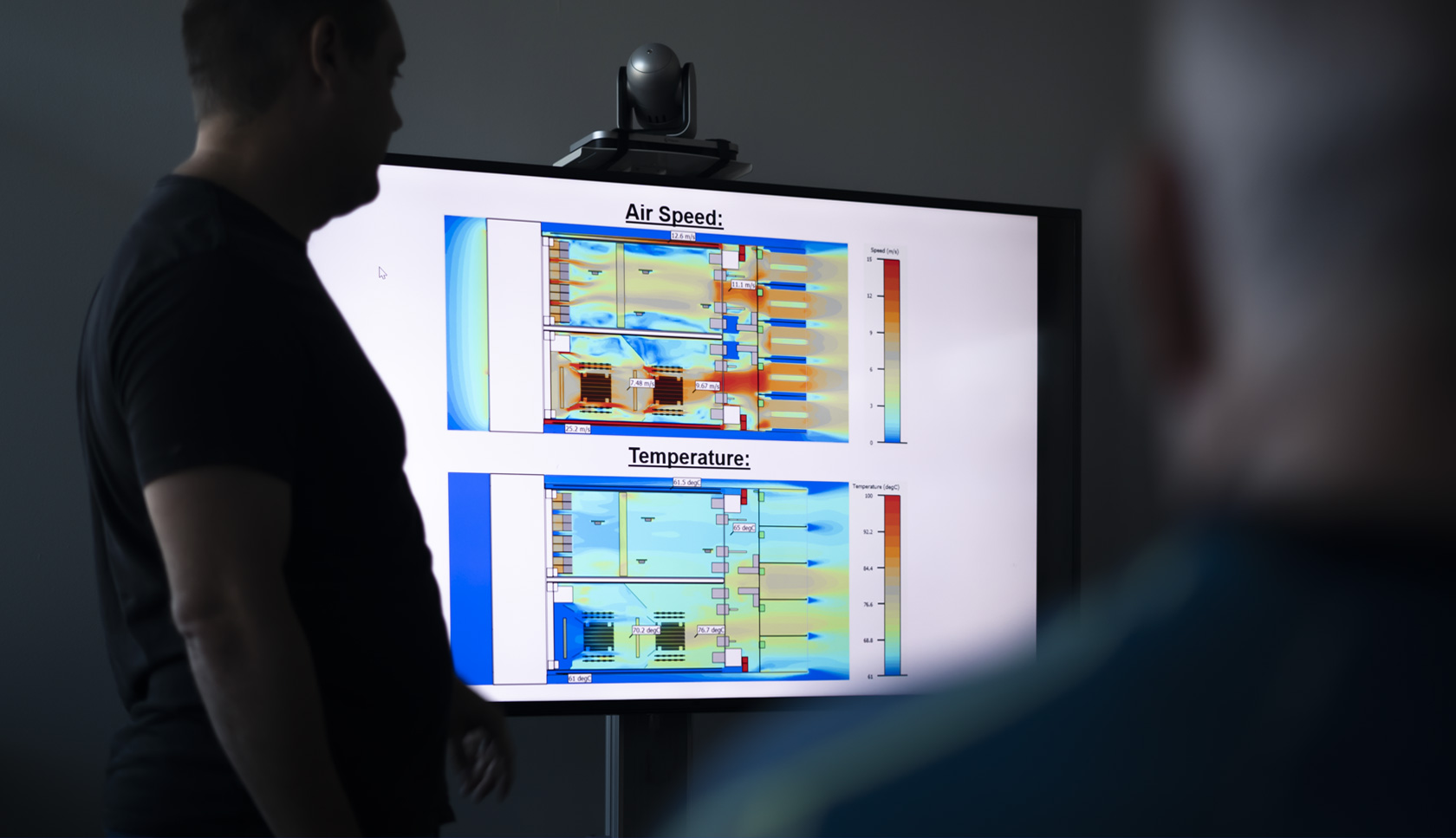

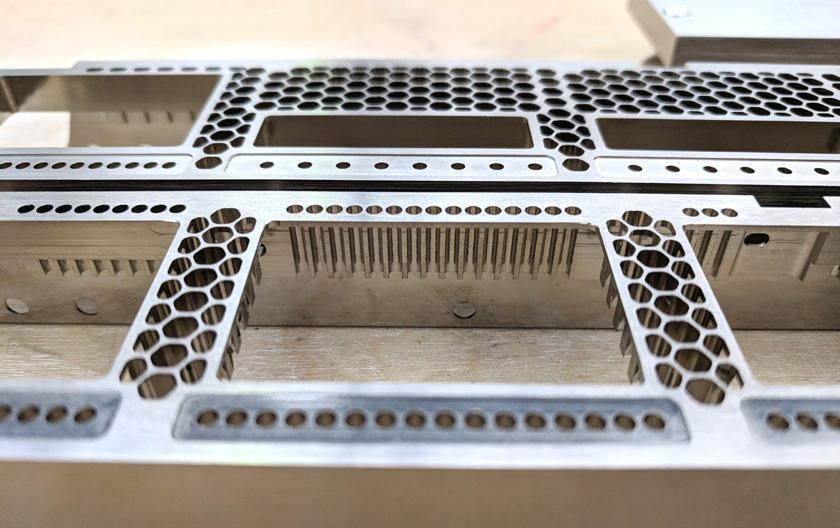

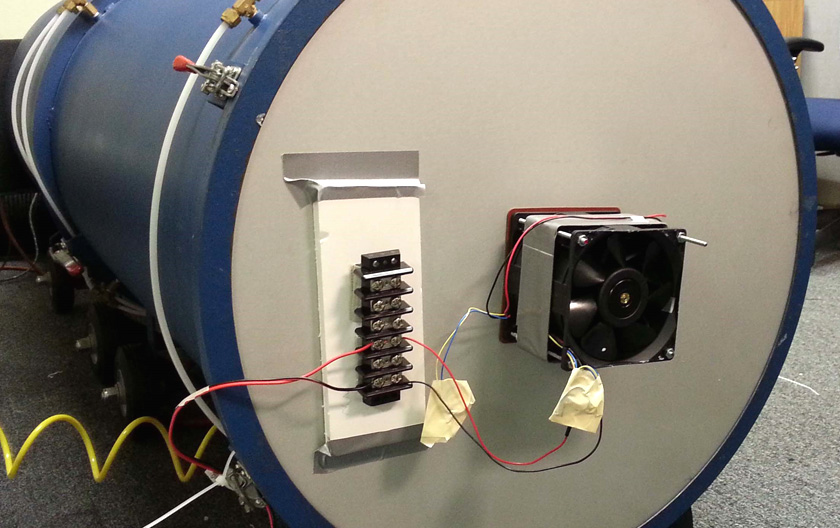

M3 partnered with Ixia, one of the premiere global providers of network solutions that help organizations to simulate, test, secure and monitor their networks to optimize performance. M3’s role was to bring new cutting edge product ideas to reality and push the boundaries of existing market density and throughput capabilities. By working closing with the Ixia team to validate new architectures, develop thermal management strategies, and ultimately design groundbreaking modular mechanical systems, M3 was able to help Ixia bring class-leading network visualization and optimization tools to market which outpaced the competition and provide more upgrade flexibility and bandwidth than the competition.