Article

Success Drivers in Action: How to Choose the Right Design Concept Every Time

Adhering to your product requirement document won’t be enough for market viability. Learn how to incorporate meaningful success drivers in product design.

It’s common for design leaders to begin a product development project by reviewing and analyzing the PRD. And to some degree, that makes sense. After all, a product requirement document gives detailed information about the features, functionalities, and capabilities a company wants its new product to contain.

But what happens when that list of requirements bumps up against real-world limitations? How should designers weigh each one in terms of importance, particularly if there are competing needs? And when push comes to shove, which requirements are truly must-haves versus nice-to-haves?

Complexities like these are precisely why we glance at the PRD and then set it aside. Instead of obsessing over a list of requirements, we focus on criteria that actually help us make good decisions and achieve the business impact our clients are looking for.

Goodbye, PRD. Hello, success drivers.

What are Success Drivers in Product Development?

At its core, product development is a tool for reaching a business objective. And success drivers are the high-level concepts and guiding principles that ensure your product meets your business needs. What success drivers aren’t, however, are a set of hard-and-fast rules that designers must follow come hell or high water.

M3 Design COO, John Bernero, explains it this way: Success drivers are to product development what a recipe is to your favorite dish. To whip up your grandmother’s famous apple pie, it’s not enough to just have a list of every ingredient. You also need to know the correct amounts for each one, the right methods to use when mixing them all together, and the conditions (e.g. consistency of the butter or oven temperature) that lead to the desired result.

But even within the confines of the recipe, there’s flexibility to modify it based on your preferences. Do you like your pie a little sweeter than the way Grandma made it? You can add more sugar to satisfy your sweet tooth. Want a lower-fat version? You can sub out ingredients to accomplish that goal.

In the same way, success drivers enable you to blend your product requirements together in a way that meets your business goals and your end users’ wants and needs. A PRD will generally present each requirement as equally important with no room for interpretation. Success drivers allow you to challenge and iterate on the checklist based on what you’re truly trying to accomplish.

3 Real-World Examples: How M3 Uses Success Drivers to Make Design Decisions

We’ve written extensively about the importance of conducting a robust strategy phase and using those findings to establish your success drivers. And we’ve also talked a lot about the value of success drivers in theory. But how do these guiding principles work in practice?

Here’s a glimpse at how we used success drivers to make smart design decisions about three actual products.

1. Luminex’s ARIES™ Molecular Diagnostics Platforms

When the biotechnology company Luminex hired M3 to redesign a newly acquired piece of lab diagnostic equipment, there were clear business objectives guiding their efforts. Their strategy phase revealed the need to:

- Free up space on the lab bench

- Bring technology to the forefront to improve usability

- Simplify serviceability to reduce downtime

- Incorporate the external PC and screen into the main device

- Create a bold, branded design language for their newly-integrated suite of products

Using these success drivers as our compass, we explored a variety of potential architectural solutions with stakeholders and learned we were much less constrained by height than by width. Therefore, we focused on creating a vertical unit to reduce the instrument’s footprint.

However, when we presented initial design concepts to Luminex, users raised concerns about the new strategy. They specifically mentioned the potential for the device to tip over, as well as the ergonomic viability of the tall architecture. To resolve conflicting stakeholder feedback, we weighed these comments against Luminex’s top success driver — optimizing bench space. Using a decision matrix to evaluate all of the active concepts against common criteria, we reached alignment that a tall concept was still the way to go.

Then we went back to the drawing board to conceptualize easier-to-use options for technicians to insert lab sample cartridges into both the top and bottom bays. That allowed us to satisfy the also-crucial success driver of improving usability.

We:

- Re-oriented the two side-by-side modules into a vertical stack, greatly reducing the instrument’s footprint

- Positioned an interactive touchscreen between the two now-vertical cartridge slots

- Added large side access panels and a hinged front door to make it easy to service the equipment

- Established the foundational concept of consolidation of components to reduce footprint which carried through into future Luminex products

The result? The tall, narrow ARIES™ system met every success driver we identified and became the first Luminex instrument to use the new design language.

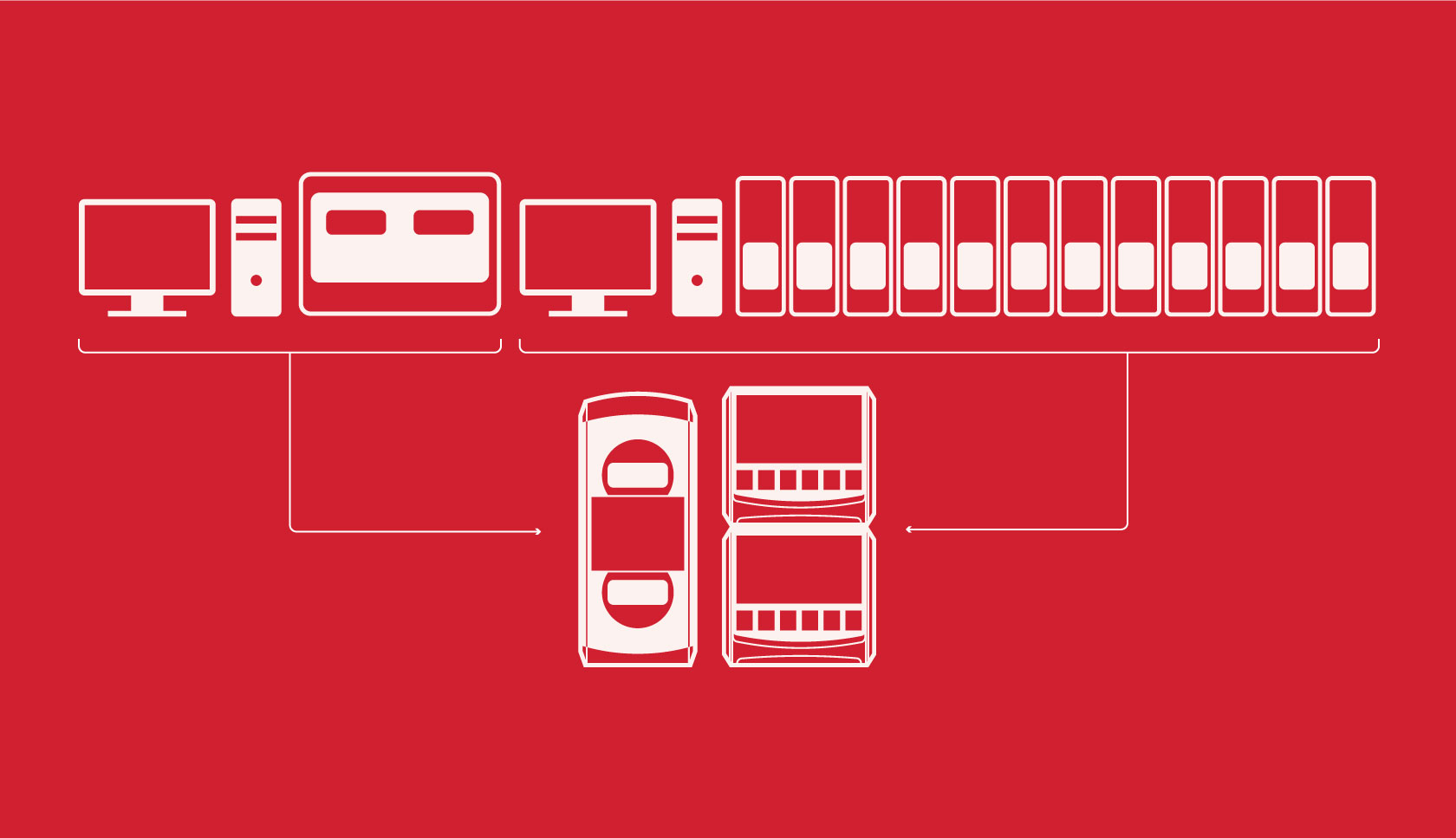

2. Everi’s Empire Electronic Gaming Platforms

Everi, a casino gaming and operations company, is passionate about giving patrons and operators alike a premium experience on the casino floor. And when they engaged M3 to redesign their popular slot machines, they did so with a variety of business challenges in mind.

Everi asked M3 to create a new design for their electronic gaming platforms that would:

- Provide casino managers with more flexibility to move machines to various locations on the casino floor in order to enhance traffic flow and promote new games

- Increase opportunities for individual or group gameplay

- Maintain easy access to the cash drawer and other frequently accessed internal components to minimize downtime

- Allow new cabinets to be created quickly

Again, using these success drivers as the basis for ideation and concept-generation, we created a revolutionary trapezoidal design that:

- Is modular and infinitely flexible. This allows casino operators to configure the machines in a variety of ways, including individually, in pods, and in non-linear, back-to-back clusters.

- Requires a smaller, compact footprint – saving up to 25 percent of floor space for some models. This enables the casino to add other games, merchandising opportunities, and rotating items of interest.

- Is stimulating and engaging. From group games and shared jackpots, the colorful, eye-catching design boosts user engagement and playing time.

One challenge is that many of the critical components within the housing are rectangular volumes. That made it difficult to package them within a trapezoidal design. In order to meet the success driver of reducing the cabinet’s footprint, we pushed Everi and ourselves to come up with creative solutions to achieve the desired size and shape. This included taking advantage of rarely used spaced behind the screens and performing intense space optimization within the base.

As a result, the Empire family of gaming platforms offers endless configuration and nesting options for a customized, user-centered gaming experience.

3. Emerson’s Micro Motion™ 1600 Compact Transmitter

Emerson creates products that solve automation and production challenges for businesses in many industries, including the highly regulated life sciences landscape. And when they identified a gap in their product portfolio, specifically in the food and beverage industry, they engaged M3 to develop a transmitter that could be used with existing Coriolis meters to measure the flow of materials and feed measurements back to the plant’s control and monitoring system.

Emerson’s success drivers were simple yet challenging. The design needed to:

- Stay within a cost-conscious budget

- Meet the specific regulatory requirements of the food and beverage industry

- Be easy to access and sterilize

- Simplify the manufacturing process of the product

We fulfilled these success drivers by:

- Analyzing the closest existing Emerson transmitter to identify design features that could be optimized. For example, the older transmitter used an expensive angled housing that added manufacturing and assembly complexity without adding value in terms of usability. Moving to a straight housing addressed these issues.

- Introducing a translucent plastic cap, which diffuses the status-LED indicator. This creates improved visibility of the state of the transmitter from various angles and from a distance.

- Replacing the internals with drop-in, plug-and-play modules that make servicing and assembly of the transmitter quick and easy.

- Opting for stainless steel rather than painted materials (paint is a no-no per food and beverage regulations).

The challenge inherent in this project was taking a design that users and stakeholders were accustomed to and adapting it for a carefully regulated, modern setting. Initially, there was an appetite to maintain the angled housing to maintain flexibility in how the transmitter was positioned to allow screen/status visibility. However, through user interviews and site visits, we discovered that most of these monitoring tasks are performed remotely. Users were really only interested in being able to check at a glance whether a device was working or not.

With this insight in mind, we felt confident pursuing what ended up being the final design direction. Pointing back to the overarching success drivers of reducing the cost per unit, improving manufacturability, and adhering to regulatory guidelines allowed us to reach alignment on a design that looks and functions much differently than past iterations.

Design Your Next Product Based on the Factors That Matter Most

Even if your product checks every box on your PRD, it can still become a market flop. Creating success drivers that connect the dots between your requirements and your business objectives is the best way to increase your odds of market success.

So don’t skip the research and strategy phase of product development. Take time to identify the business objectives that are critical to your product’s ultimate success. And above all, don’t go it alone.

M3 knows how to make smart decisions in every phase of the product development process. So when you’re ready to take your next product idea from concept to completion, just reach out.